Kuwayama actively engages in a diverse range of researches associated with jewellery.

Technologies and equipment developed through these researches are supporting manufacturing of many products today.

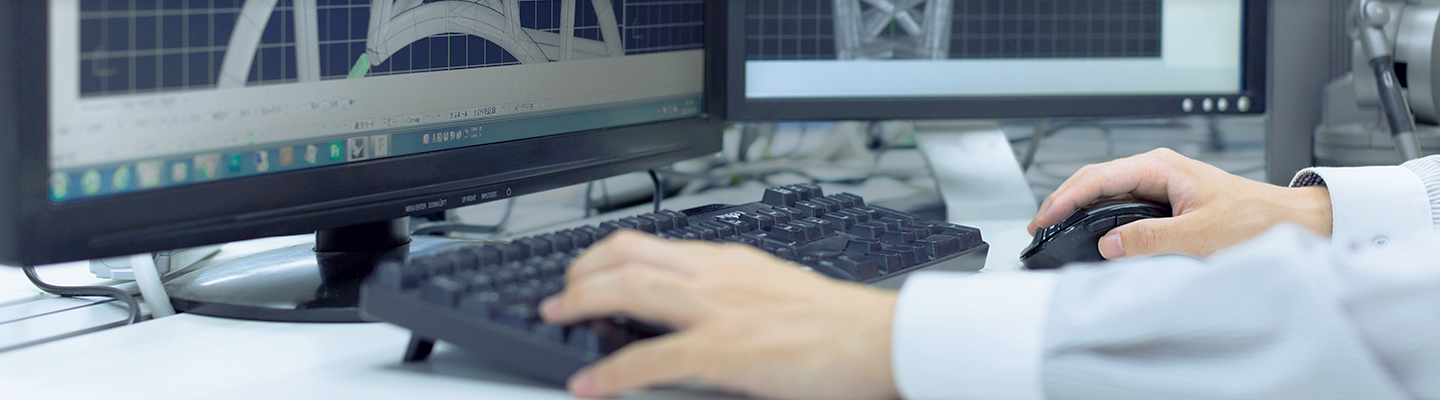

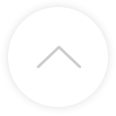

3D Technology

Kuwayama is among the first in the jewellery industry driving forward 3D computer-aided designing by introducing state-of-the-art 3D devices such as 3D printers and high-precision scanners. Through the right use of various different CAD software to fit for purposes, Kuwayama has been developing new products taking advantage of the characteristics of CAD, thereby attracting much attention both domestically and internationally.

Wao

Wao (Ring King) is a Kuwayama's original clasp developed in pursuit of superior usability by shaping a comfortable-to-pull angle and larger size of the finger-grip part to generate stabile feeling. Paying extra attention to the action of pulling, Kuwayama has formulated this unique structure considering the force-application point. This product was created through Kuwayama's research & development efforts standing on the viewpoint of customers who use this product.

Designed Balls

Utilizing state-of-the-art production technologies, Kuwayama also engages in development of equipment to reinforce its manufacturing capabilities. One example is the "automatic designed-ball-cutting machine" used to manufacture designed balls that decorate chains. Developed jointly with a machinery manufacturer, this machine has enabled mass and automated manufacturing of original cut balls.

Hardened Platinum

High-purity precious metals are relatively low in strength. Platinum, which is rarer than gold, is popular as bridal rings thanks to its characteristic highly resistant to deterioration, but if its purity is kept high, it may easily get scratched due to its softness. To address this, Kuwayama has developed a patented technology to harden platinum while also maintaining high purity.